PVD-Materials

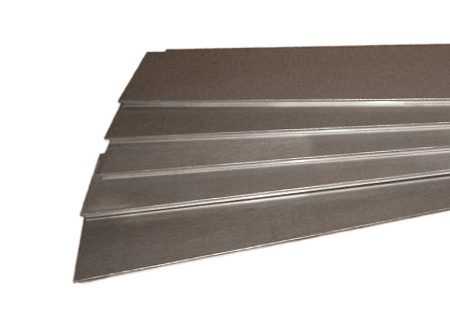

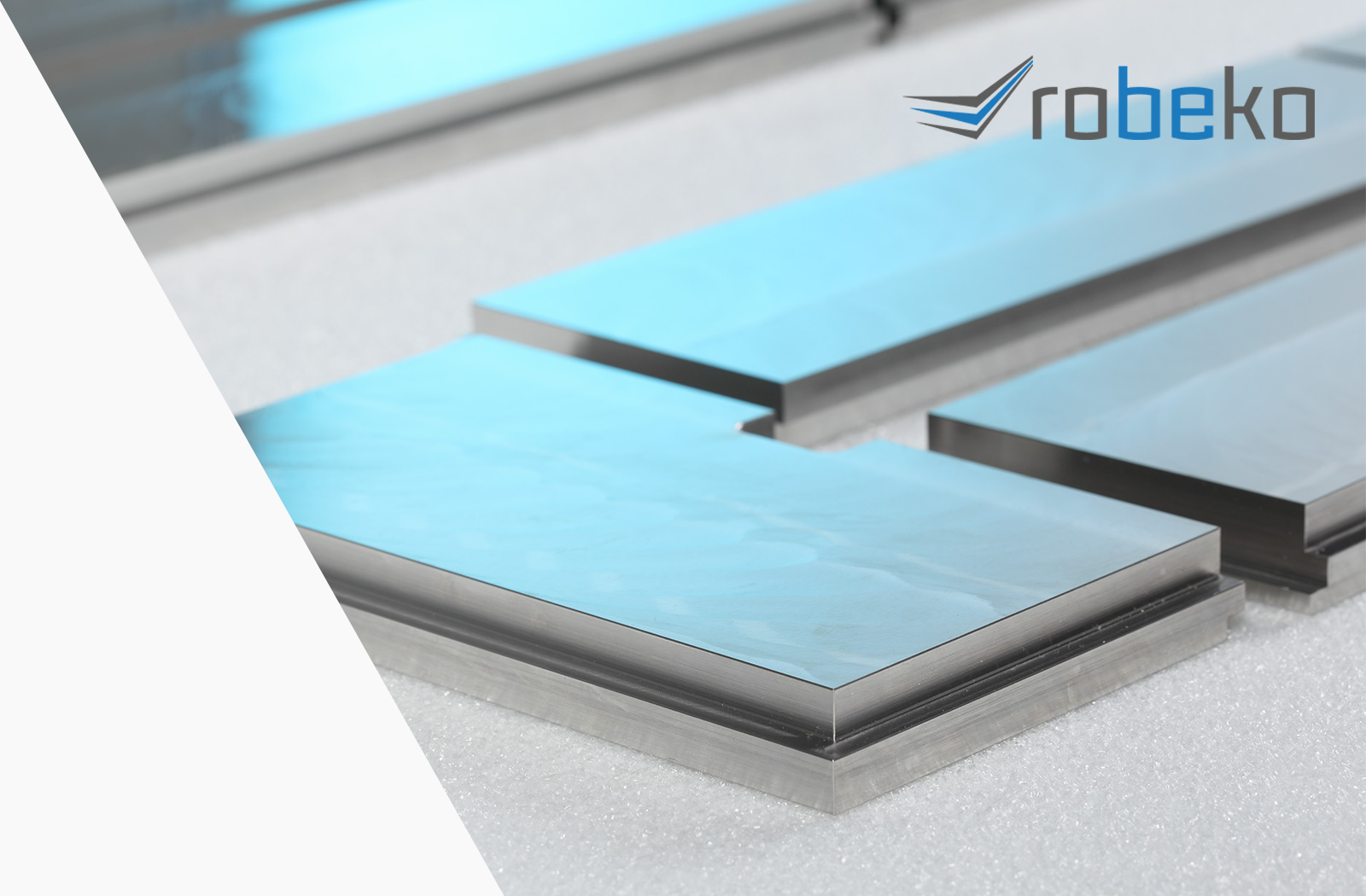

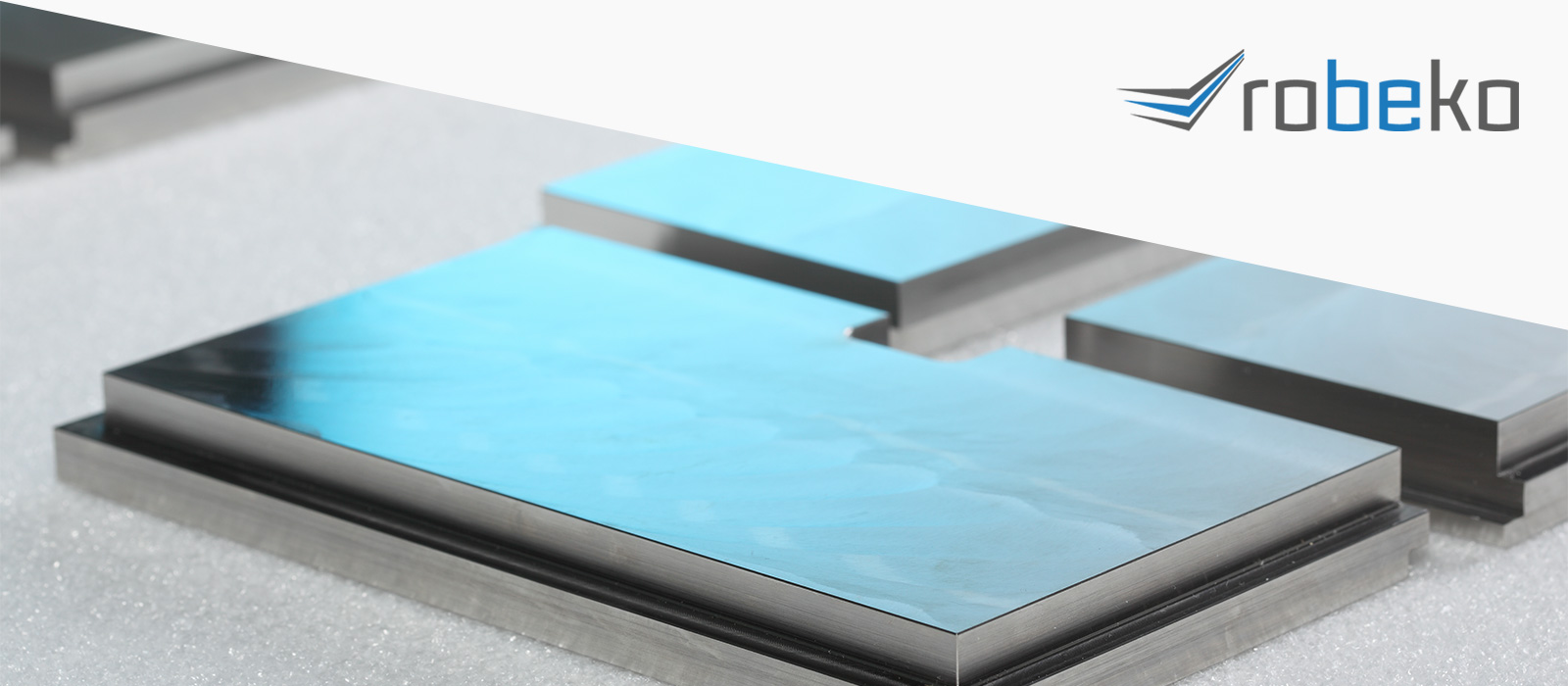

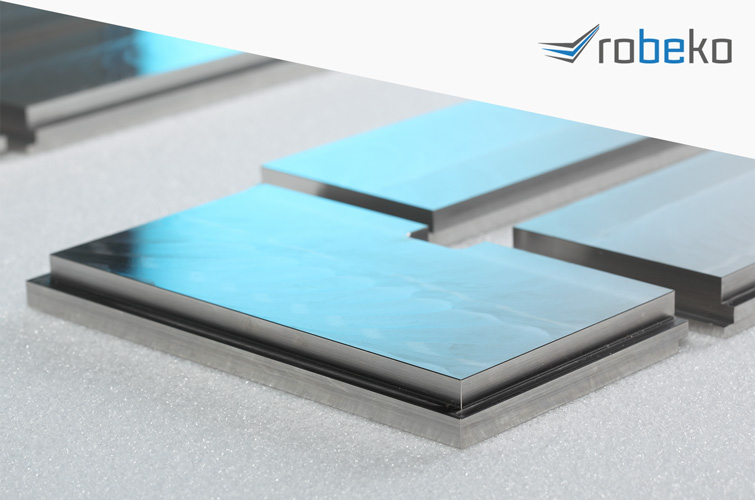

SPUTTER TARGETS

robeko offers a wide range of high performance thin film coating materials for magnetrons of all manufacturers and a variety of applications such as large area coatings, precision optics, touch panels, tribological and decorative coatings.

Our supply chain consists of in-house manufacturing capabilities combined with long-term partnerships to ensure maximum quality, minimum lead times and highly competitive pricing.

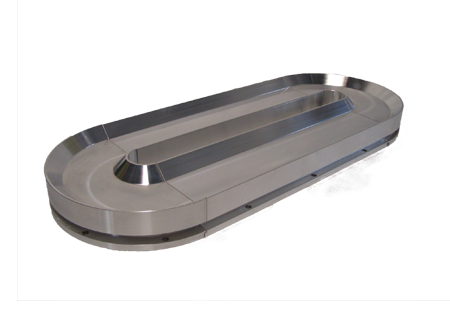

SPUTTER TARGETS

robeko offers a wide range of high performance thin film coating materials for magnetrons of all manufacturers and a variety of applications such as large area coatings, precision optics, touch panels, tribological and decorative coatings.

Our supply chain consists of in-house manufacturing capabilities combined with long-term partnerships to ensure maximum quality, minimum lead times and highly competitive pricing.

SPUTTER TARGETS

robeko offers a wide range of high performance thin film coating materials for magnetrons of all manufacturers and a variety of applications such as large area coatings, precision optics, touch panels, tribological and decorative coatings.

Our supply chain consists of in-house manufacturing capabilities combined with long-term partnerships to ensure maximum quality, minimum lead times and highly competitive pricing.

EVAPORATION

MATERIALS

MATERIALS

robeko – evaporation materials are used in many different applications, e.g. electron beam and thermal evaporation. Our extensive range includes materials for ophthalmic products, precision optics, contact coatings, micro-electronics, etc.

We supply tablets, pellets and granules in various optimized mesh sizes.

EVAPORATION MATERIALS

robeko – evaporation materials are used in many different applications, e.g. electron beam and thermal evaporation. Our extensive range includes materials for ophthalmic products, precision optics, contact coatings, micro-electronics, etc.

We supply tablets, pellets and granules in various optimized mesh sizes.

EVAPORATION

MATERIALS

MATERIALS

robeko – evaporation materials are used in many different applications, e.g. electron beam and thermal evaporation. Our extensive range includes materials for ophthalmic products, precision optics, contact coatings, micro-electronics, etc.

We supply tablets, pellets and granules in various optimized mesh sizes.

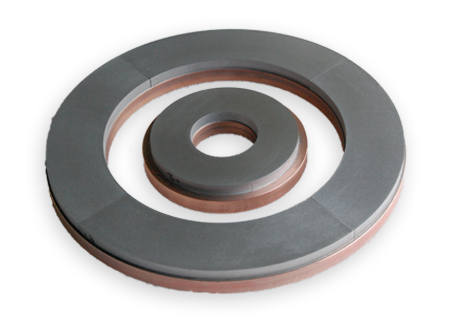

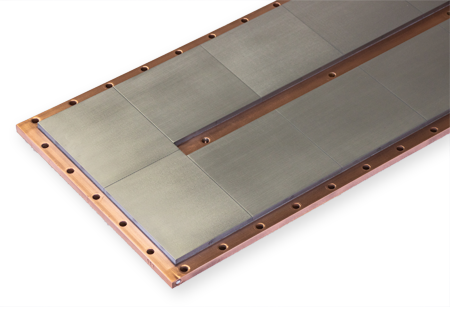

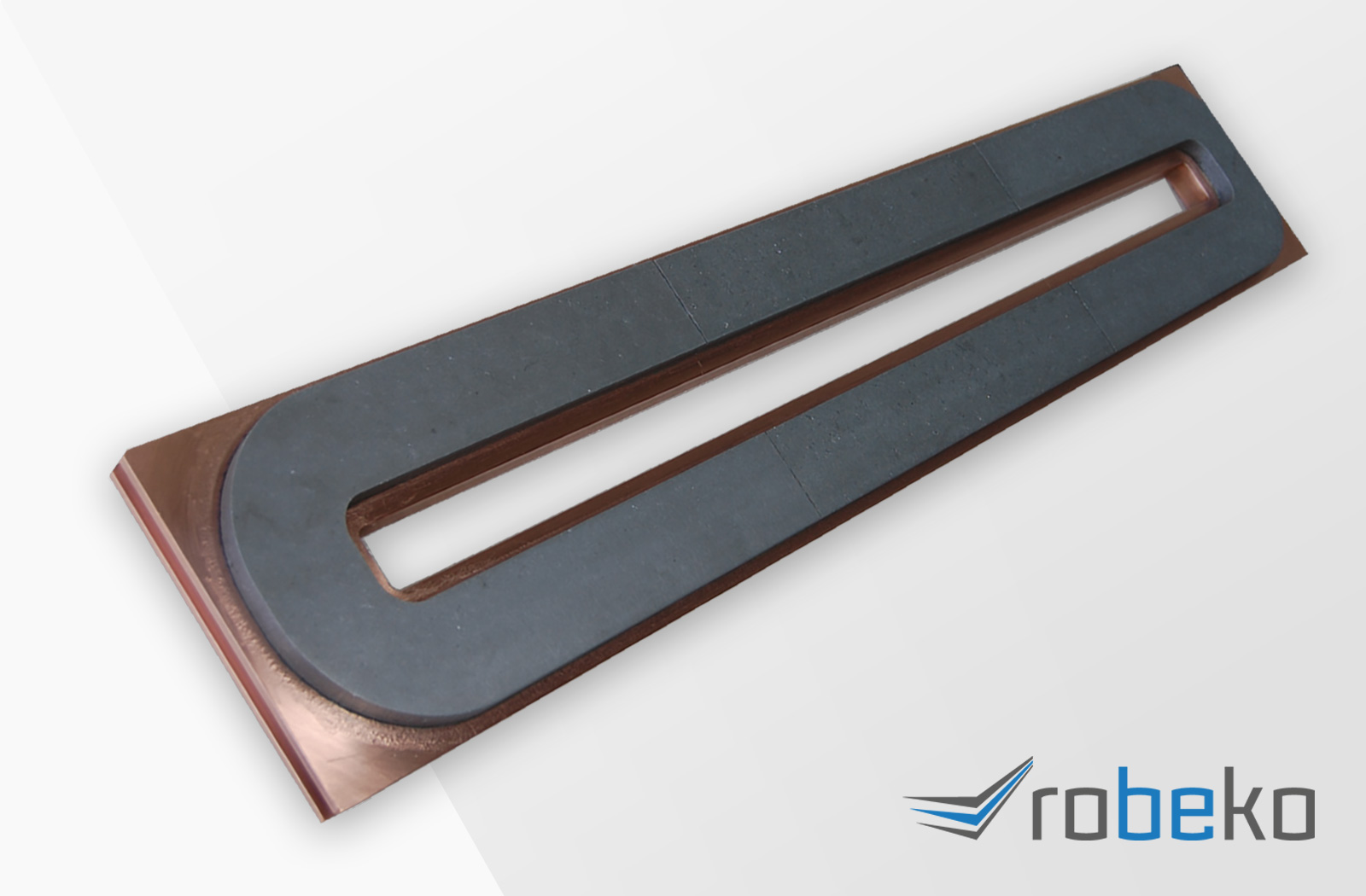

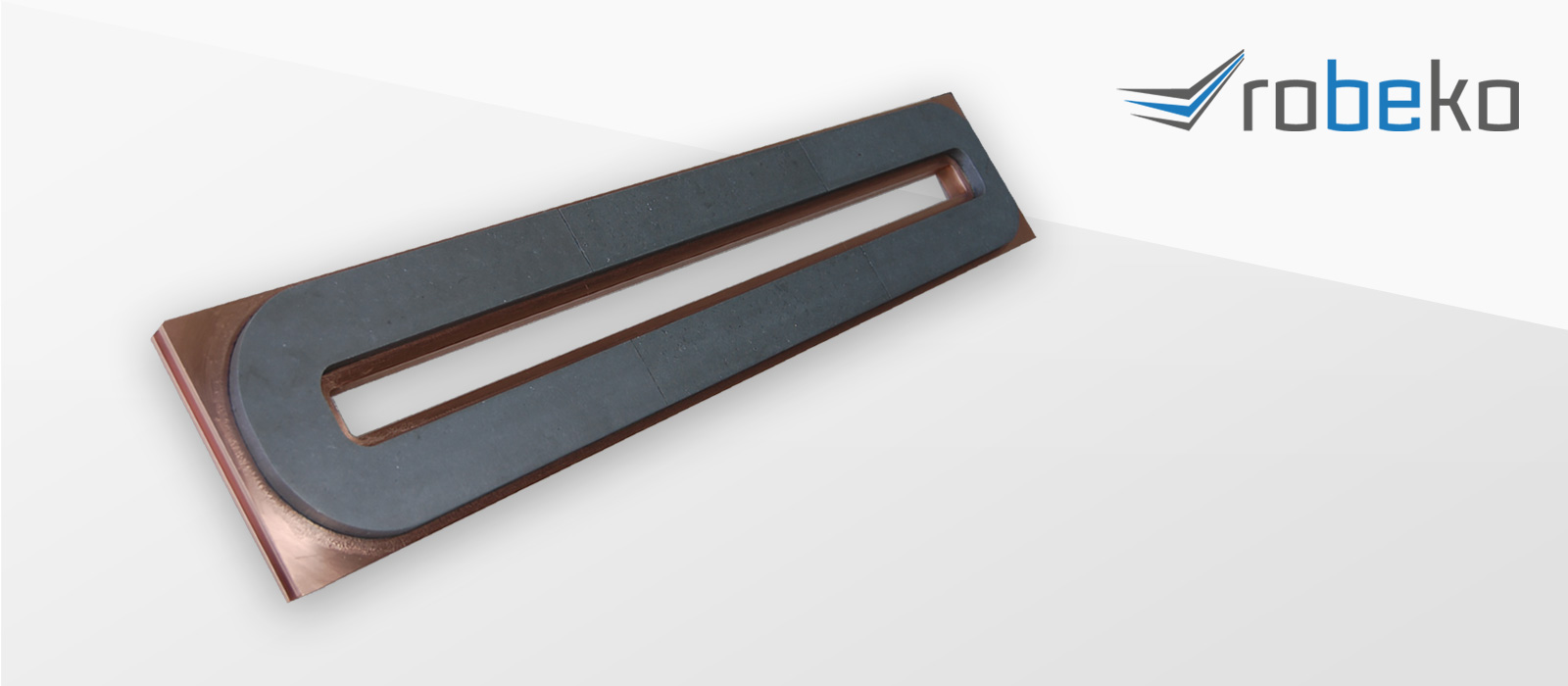

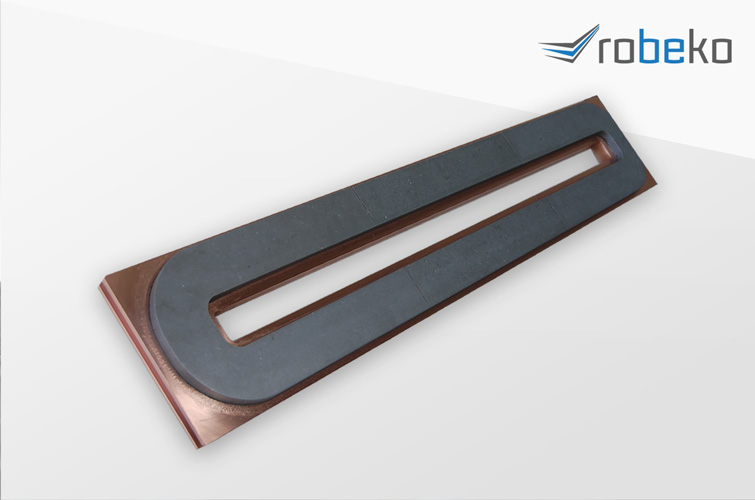

TARGET BONDING

Many sputtering targets must be bonded to a backplate or magnetron heat sink. In high sputtering applications, proper bonding is essential to ensure the mechanical stability of the target to prevent cracking, deformation and delamination. Our company has employees with decades of experience in this area who can provide you with in-depth advice and support in selecting the appropriate process. The right choice of bonding layer, diffusion barrier and the related optimal bonding method is the prerequisite for perfect results.

TARGET BONDING

Many sputtering targets must be bonded to a backplate or magnetron heat sink. In high sputtering applications, proper bonding is essential to ensure the mechanical stability of the target to prevent cracking, deformation and delamination. Our company has employees with decades of experience in this area who can provide you with in-depth advice and support in selecting the appropriate process. The right choice of bonding layer, diffusion barrier and the related optimal bonding method is the prerequisite for perfect results.

TARGET

BONDING

BONDING

Many sputtering targets must be bonded to a backplate or magnetron heat sink. In high sputtering applications, proper bonding is essential to ensure the mechanical stability of the target to prevent cracking, deformation and delamination. Our company has employees with decades of experience in this area who can provide you with in-depth advice and support in selecting the appropriate process. The right choice of bonding layer, diffusion barrier and the related optimal bonding method is the prerequisite for perfect results.

![]()