PECVD-Technology

APPLICATION CENTER

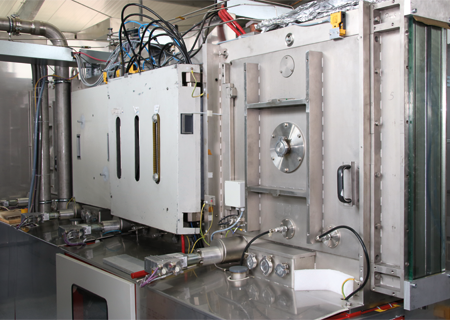

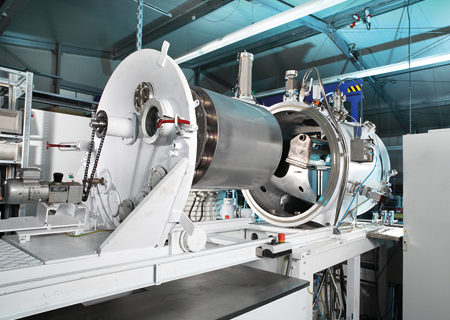

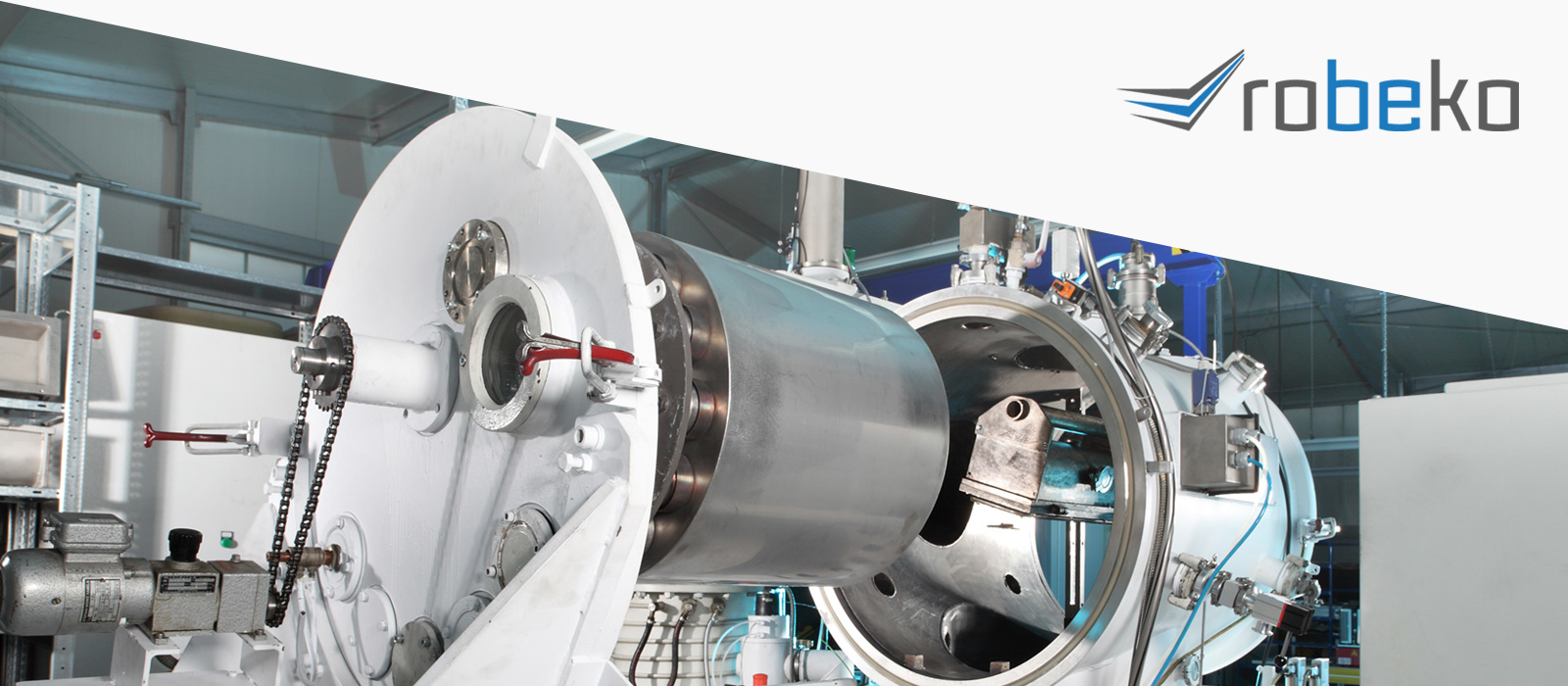

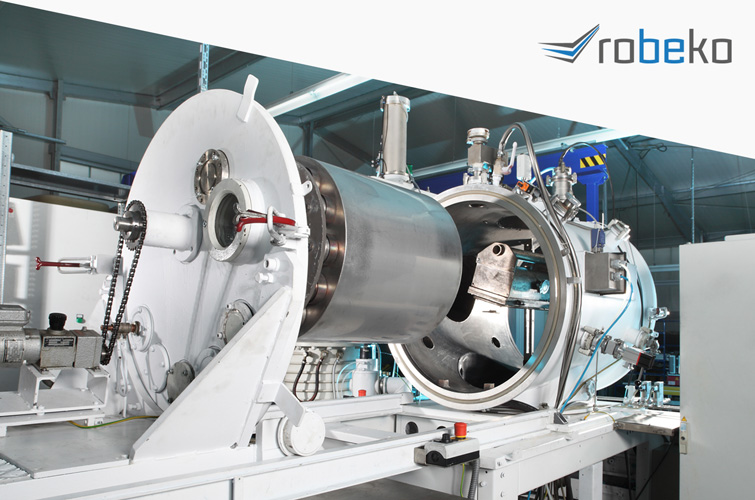

An outstanding unique feature of robeko is the possibility to investigate, test or verify PVD & PECVD processes in our own application center. This can involve the testing of new components, the development of prototype coatings or the testing of new materials. The equipment with corresponding systems up to the inline sputtering system with several stations allow a process control under conditions of industrial series production.

APPLICATION CENTER

An outstanding unique feature of robeko is the possibility to investigate, test or verify PVD & PECVD processes in our own application center. This can involve the testing of new components, the development of prototype coatings or the testing of new materials. The equipment with corresponding systems up to the inline sputtering system with several stations allow a process control under conditions of industrial series production.

APPLICATION

CENTER

CENTER

An outstanding unique feature of robeko is the possibility to investigate, test or verify PVD & PECVD processes in our own application center. This can involve the testing of new components, the development of prototype coatings or the testing of new materials. The equipment with corresponding systems up to the inline sputtering system with several stations allow a process control under conditions of industrial series production.

LAYER DEVELOPMENT

Our R&D department, staffed by 4 scientists with degrees in physics and chemistry, is focused on developing and testing new coating systems for our customers. This is not only about selecting the right materials and layer sequences, but we also support our customers in choosing the right equipment and methods to ensure the optimal result, also in terms of long-term total investment costs. We also support our technology partners in the development of new products that can be tested on our equipment.

LAYER DEVELOPMENT

Our R&D department, staffed by 4 scientists with degrees in physics and chemistry, is focused on developing and testing new coating systems for our customers. This is not only about selecting the right materials and layer sequences, but we also support our customers in choosing the right equipment and methods to ensure the optimal result, also in terms of long-term total investment costs. We also support our technology partners in the development of new products that can be tested on our equipment.

LAYER-

DEVELOPMENT

DEVELOPMENT

Our R&D department, staffed by 4 scientists with degrees in physics and chemistry, is focused on developing and testing new coating systems for our customers. This is not only about selecting the right materials and layer sequences, but we also support our customers in choosing the right equipment and methods to ensure the optimal result, also in terms of long-term total investment costs. We also support our technology partners in the development of new products that can be tested on our equipment.

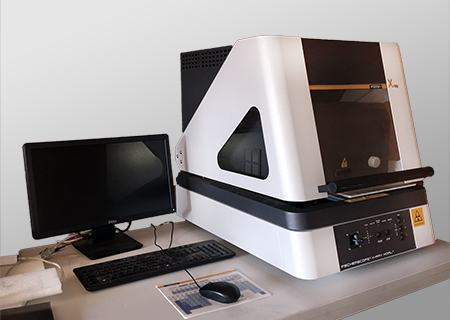

IMMEDIATE ANALYSIS

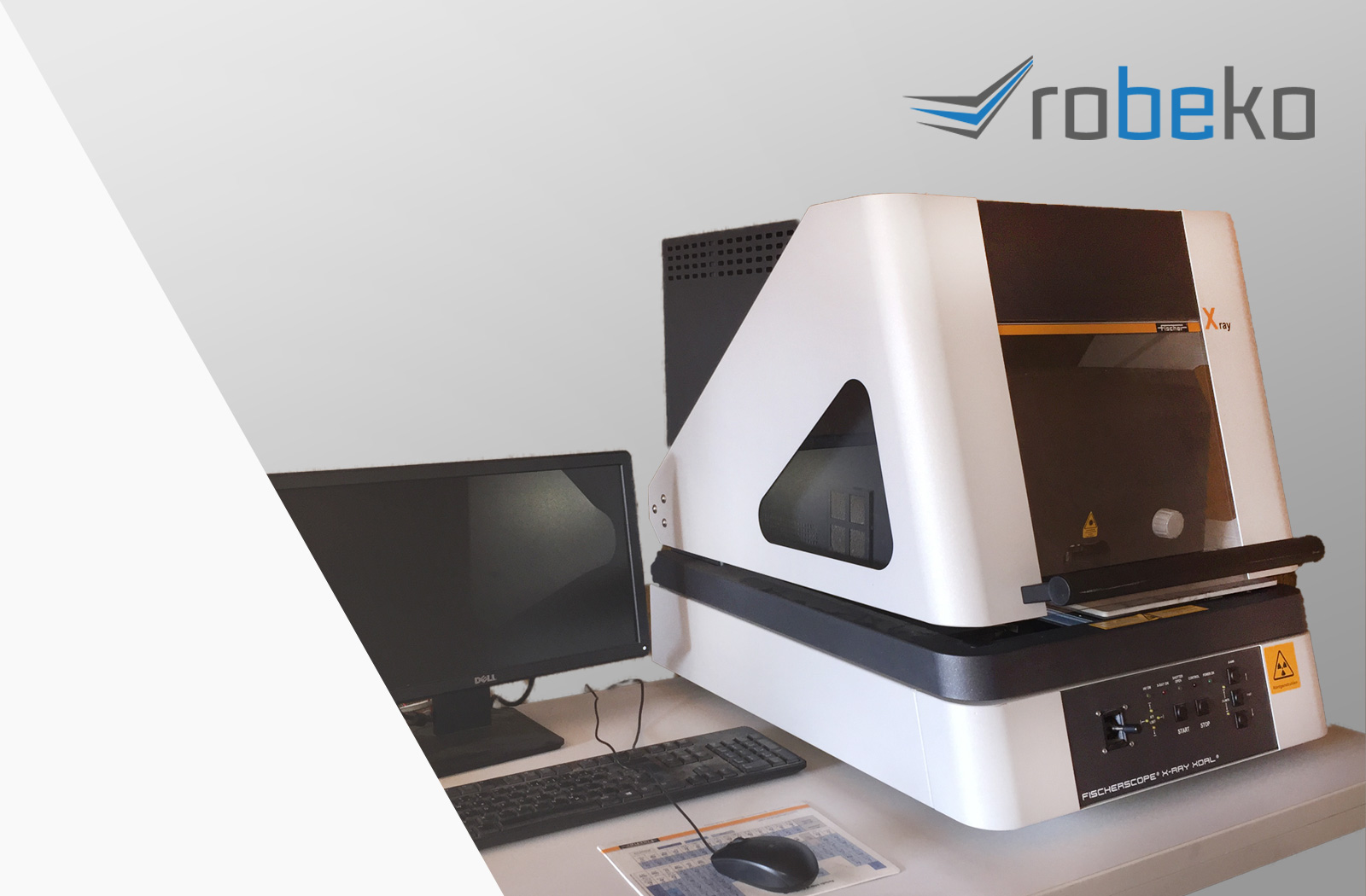

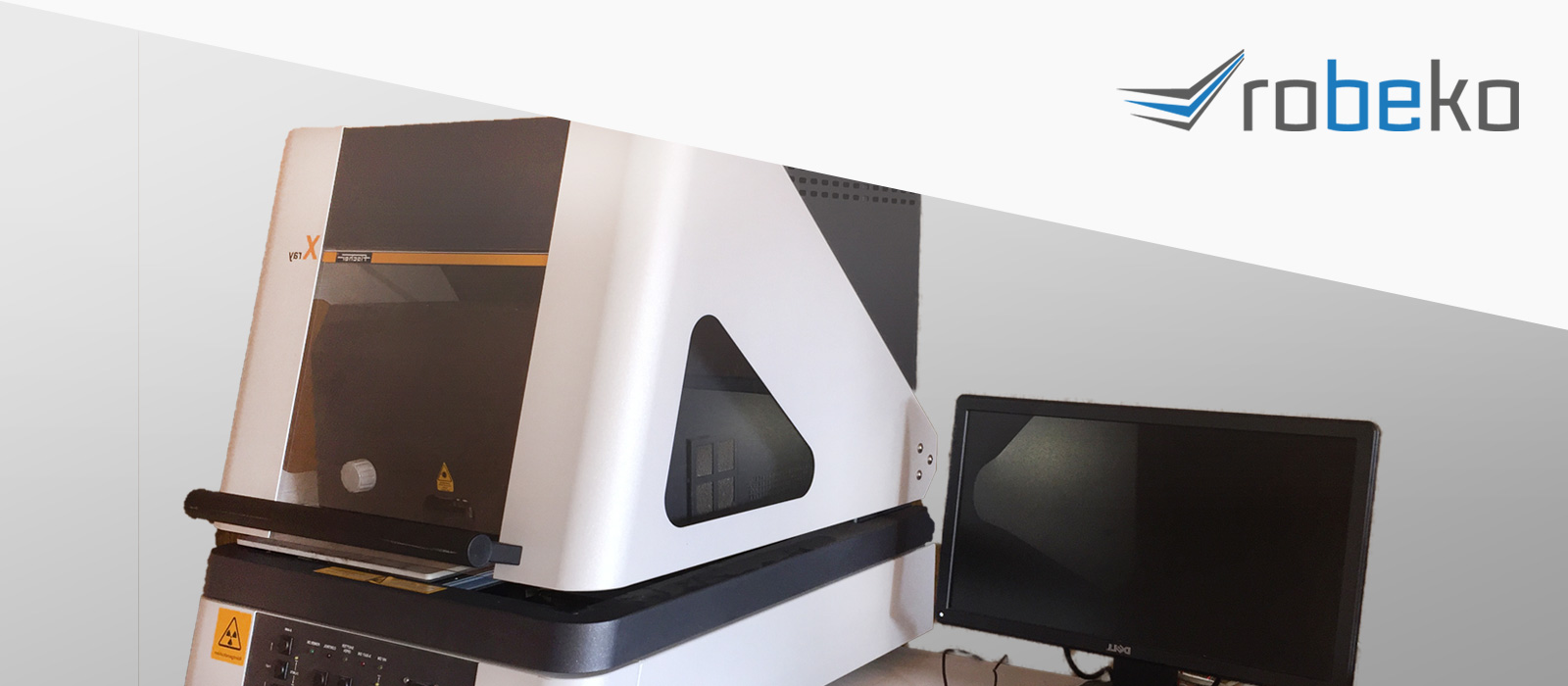

In order to be able to evaluate the results obtained in a short time, it is indispensable to have a good basic equipment of laboratory instruments for coating analysis. Fast, direct analyses with professional equipment allow the parameters of the tests carried out to be adjusted at short notice and thus the number of iterations to determine the optimum result in the shortest possible time.

IMMEDIATE ANALYSIS

In order to be able to evaluate the results obtained in a short time, it is indispensable to have a good basic equipment of laboratory instruments for coating analysis. Fast, direct analyses with professional equipment allow the parameters of the tests carried out to be adjusted at short notice and thus the number of iterations to determine the optimum result in the shortest possible time.

IMMEDIATE-

ANALYSIS

ANALYSIS

In order to be able to evaluate the results obtained in a short time, it is indispensable to have a good basic equipment of laboratory instruments for coating analysis. Fast, direct analyses with professional equipment allow the parameters of the tests carried out to be adjusted at short notice and thus the number of iterations to determine the optimum result in the shortest possible time.

![]()